In the eyes of Preston F. Tucker, the American car of just after the end of World War II was totally out-of-date. Most car buyers at that time saw the Buick straight-eight – a large, heavy and conservative model – as the car they aspired to owning.

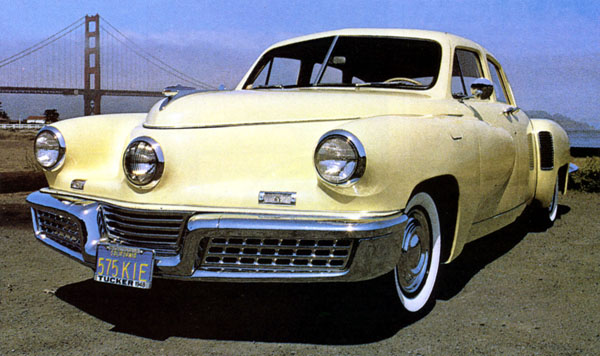

With his 1947 Torpedo, Tucker offered a rear-mounted, flat-six engine with hydraulic valve actuation, sealed cooling system, torque converter-transmission, all-independent suspension and disc brakes. He also included special in-built safety features such as pop-out windscreen, crash padding and break-away mirror – a good 20 years before Ralph Nader lined the American motor industry up in his sights. No car, past or present, has carried as many design innovations

Today very few people have any knowledge of the Tucker enterprise except for a few aficionados. Preston Tucker’s engineering knowledge was scant and what knowledge he had was acquired whilst working with racing car designers. But the man had a strong imagination, a bold approach and was totally dedicated to the motor car. To satisfy his dream of building the perfect car he rounded up some remarkable talent. Designers and engineers from other successful companies joined him in pushing his cause.

The specification they arrived at was completely unorthodox. Porsche-like, the engine had around 100 patented features. It was a horizontally-opposed six cast in aluminium with integral heads, chromed cylinder bores and a cast magnesium sump, and its direct fuel-injection was by means of a diesel-type pump. Although a very compact unit it produced 112 kW. It had the world’s first sealed cooling system and suspension front and rear was by rubber cartridges attached to upper and lower wishbones with anti-roll bars. Although disc brakes were used they were not of the calliper type used today but more like a clutch plate lined with friction material which was forced hydraulically against a cast iron disc.

Preston Tucker was extremely safety conscious and insisted on generous crash padding all round. Recessed door handles and a mirror with breakable stem were other features, while the windscreen, set in rubber, was designed to pop out if it received a strong blow from inside. Tucker originally wanted to install seatbelts in all positions but was dissuaded on the grounds that it was bad psychology.

The first development car was completed in 100 days. It was first shown to the public in 1947 and orders poured in following a tremendous reaction. Tucker acquired a plant previously used by Dodge to produce aero engines and set about tooling up for 1000-cars-per-day output while engineers rushed to finalise the design. Two early Tucker prototypes were rigorously tested on the racetrack and slowly problems began to arise.

The hydraulic valves needed plenty of oil before they would work satisfactorily, making starting difficult. A 24-volt starter cured that problem but there were other problems with it and the transmission. All of these took time to rectify, further delaying production.

While the first Torpedos were hand-built Tucker’s application for a government loan was turned down. Tucker was clearly in trouble and had bitten off more than he could chew. The Tucker Corporation was finally taken over by federally appointed trustees. Only 150 engines and 49 cars had been built. Together with the prototype, the total Tucker production was 50 cars. Tucker was charged with defrauding shareholders and dealers but after a long court case he was found innocent.